What we do

Our mission at Tubender is to democratize manufacturing by making automatic metal conduit-bending machines portable and easier to use. Our primary focus is to empower electricians of all experience levels by improving their conduit-bending throughput and accuracy, while ensuring that technical expertise is never a barrier.

Why Tubender?

The average data center uses 28 miles of conduit, equal to 5x the height of Mount Everest! Half of this conduit-bending is still being done using manual methods.

Tubender offers an innovative solution for precision metal conduit bending, catering to electrical contractors who are working on data center projects worth over $100 Million. Our portable CNC machines can save electrical contractors up to $5 Million in wasted labor and material costs on project sizes over $100 Million.

Safe

Above all, Tubender strives to make conduit installations safer for electricians and has multiple systems in place to ensure safe operation.

Automatic

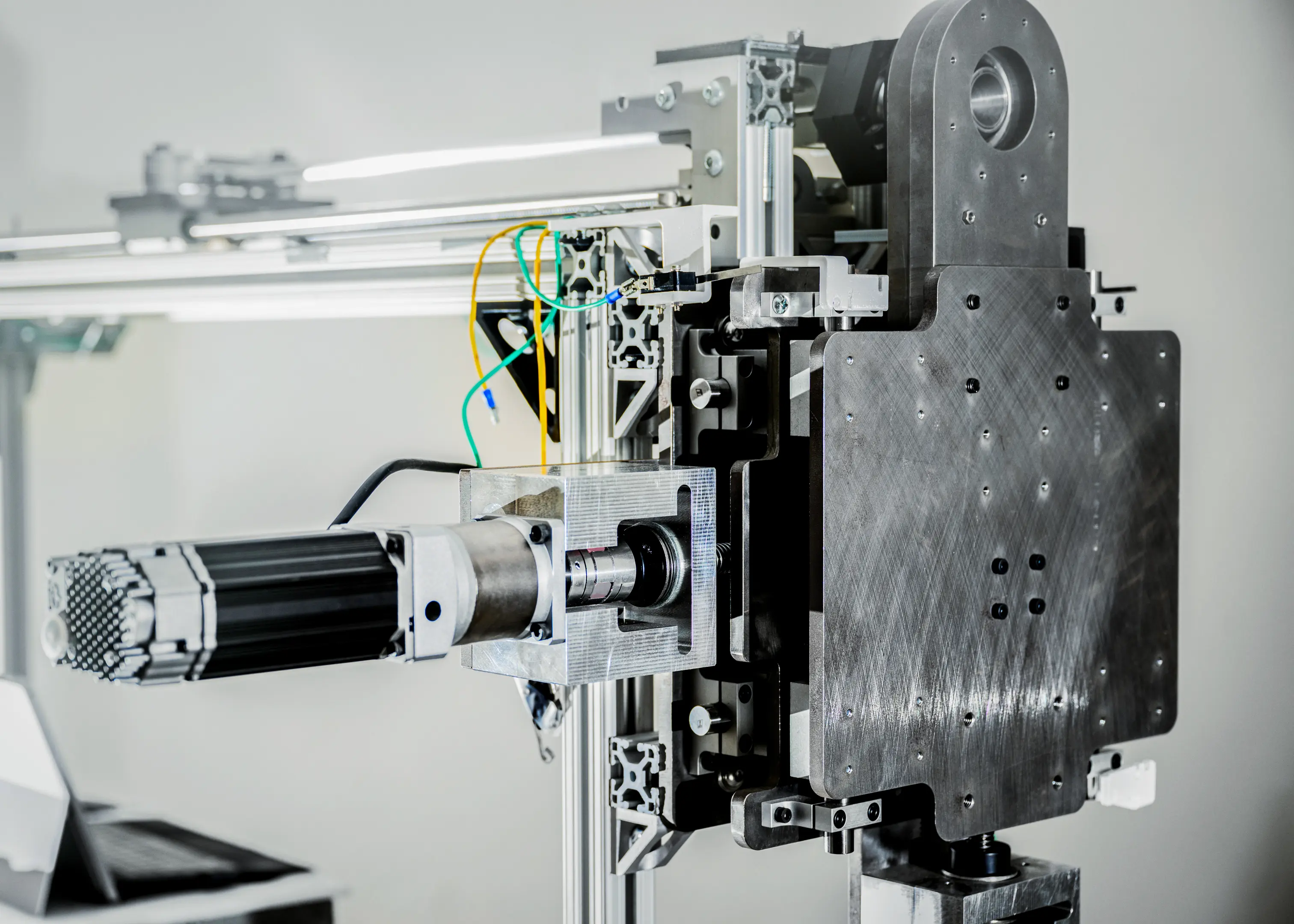

Tubender reduces labor time with CNC software control that produces all the bends in one-go. We use bending terms electricians already understand, such as offsets, stub-90s, and saddles.

Portable

Our machine is small enough to fit in a standard pickup truck, and can effortlessly be moved around the job site. Our machine is only 5 feet long and yes, it can still bend standard conduit lengths of 10+ feet.

Fast

Electricians can bend conduit up to 5x faster than current manual methods. No more need to measure, mark and reposition the tube for every bend.